Signotron has research and development experience of more than 35 years in the field of Power Electronics , Embedded Electronics and control for rolling stock and Industrial application.In this journey , Signotron developed expertise in many domains in Electronics and Electrical Engineering fields. For SMPS and Battery charger applications Buck , Boost , Buck Boost , Flyback , Pushpull , Forward , Bridge , dual active bridge topologies are used in hard switching and soft switching mode as per requirement . For Inverters and VVVF AC Motor drives Flyback , Half Bridge and single phase , three Phase Bridge topologies are used . . .

Public Address and Passenger Information System (PAPIS) and End of Train Telemetry System (EOTT)

Underslung Regulated Battery Charger cum Emergency Battery chargers for all types of LHB coaches

SMPS based power supply panel for S & T

12 kW Battery charger for Electric Loco with IGBT based front end

Underslung regulated battery chargers for all types of LHB coaches

Compact Emergency Inverter for HVAC systems for Metro Railways

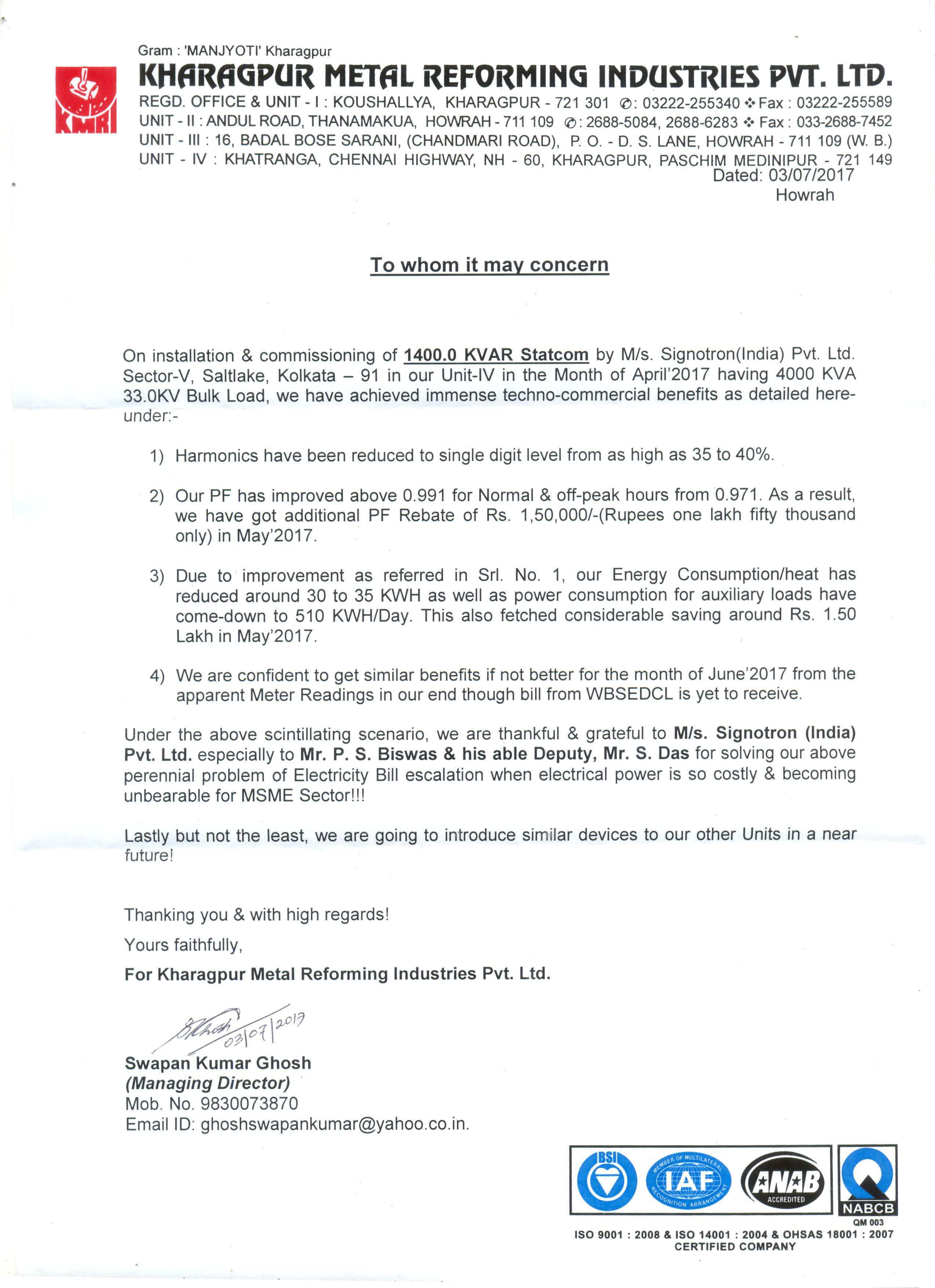

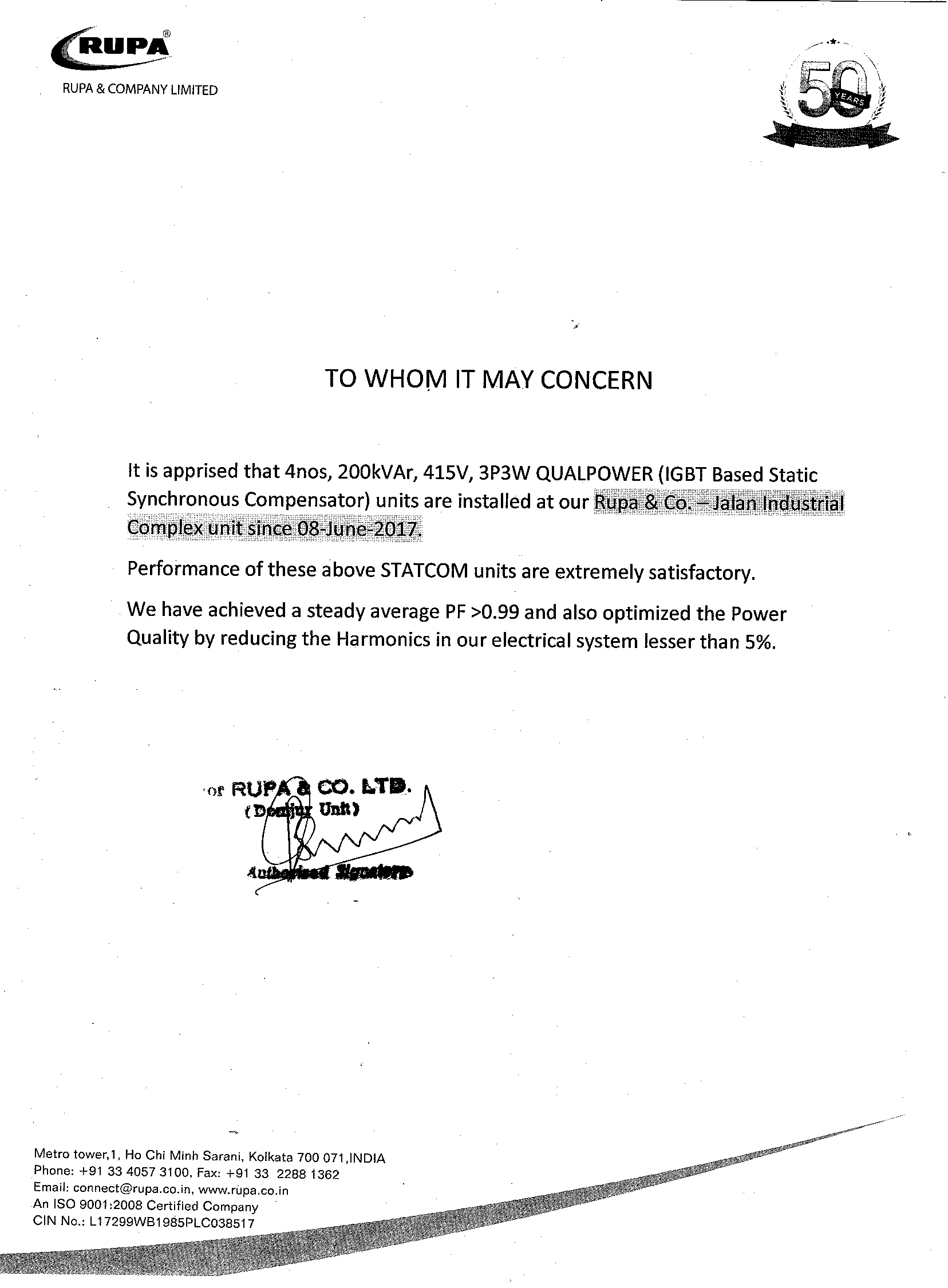

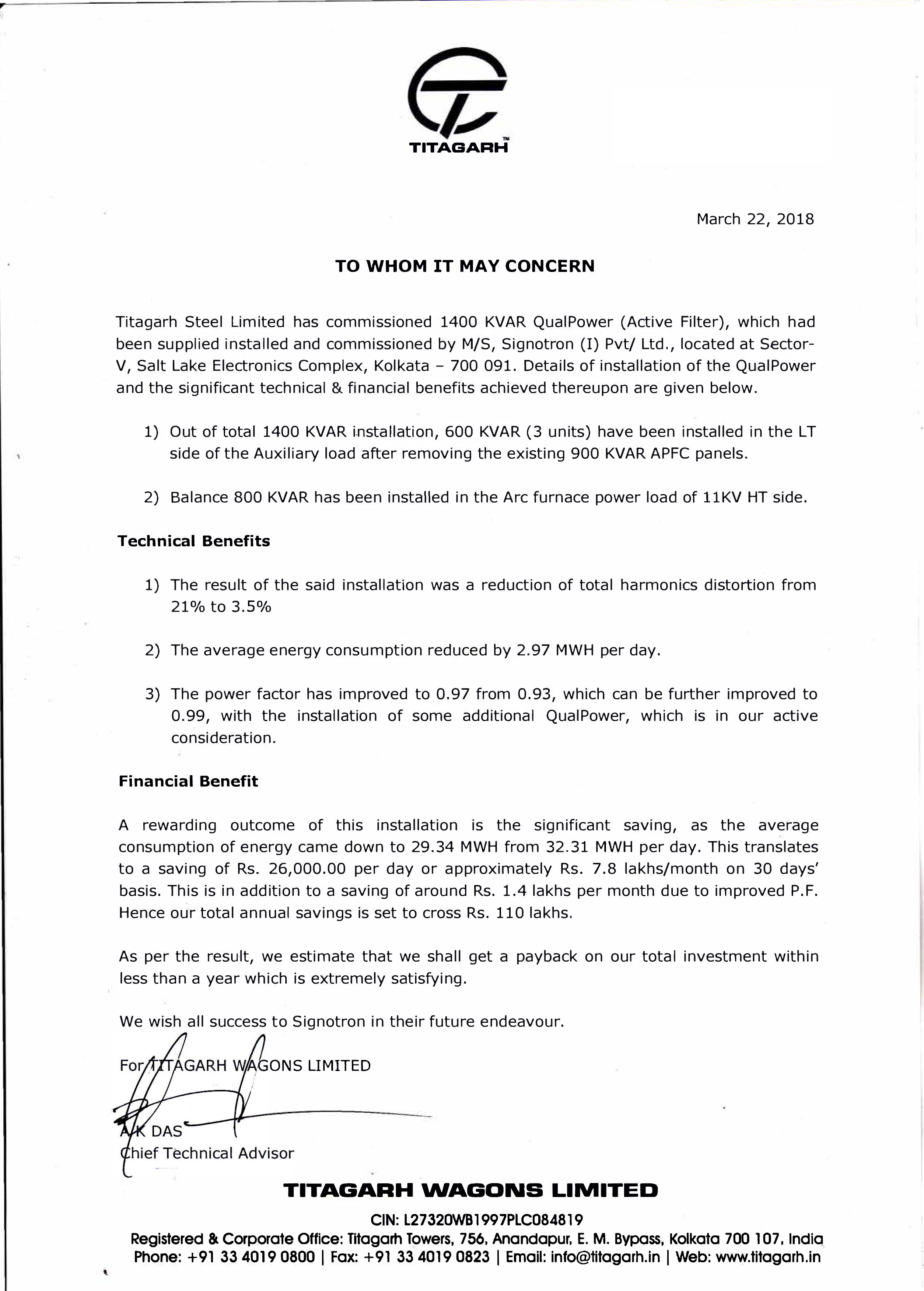

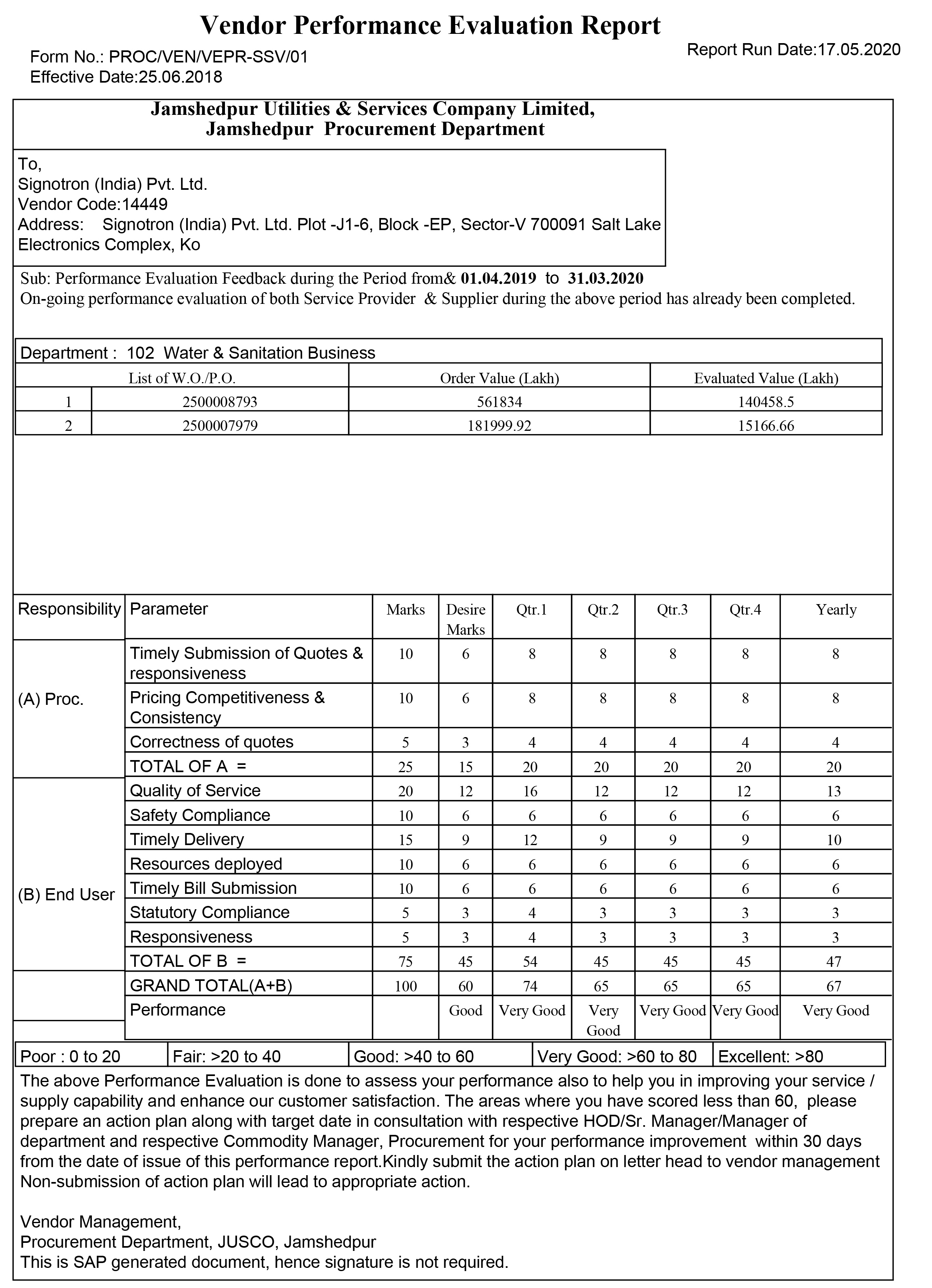

Active Harmonic filters in industries for improving power factor to near unity and reduction of current harmonics

SignoFlex EV20 SMPS for E rickshaw Battery charging

180 KVA Auxiliary Converter for electric locos

SignoFlex (HFC 6-3) Battery Charger

Turnkey solution for DC systems in power utility

Solar Power Plant designing & installation

Emergency Inverter for HVAC systems for Metro Railways

25 KVA Inverter for SGAC coaches of Indian Railways

Output paralleling of grid-interactive 3 phase solar inverters

Web-based remote monitoring and control (SCADA) for solar inverters

Grid-tied Solar Inverter up to 100 KW rating introduced

Static VAR compensator for Power Factor improvement, introduced

IGBT based Battery Charge / Discharge panel with active PFC up to 70 KW

28 KW naturally-cooled Battery Charger with active P.F.C. for SGAC coaches of Indian Railways

Supplied more than 1000 units to Indian Railways to date

Thyristor based Battery Charger with regenerative Discharging for VRLA batteries up to 70 KW

Commencement of Bulk Production of 3 phase Compact drives. Now full diesel fleet of Indian Railways has been installed with such compact drives. Total field population around 14000 as of date

Field trials of small AC Motors with Built-in Inverters by Indian Railways for 100% replacement of existing small DC Motors

Prototype unit for 3 phase Compact drive for Pump and Blower Motors for Diesel Locomotives in place of DC Motors

Inverters 0.5 KVA to 5 KVA for Pantry Car applications

5 KW DC-DC Converters for Hotel load applications of Diesel Locomotives for Sri Lanka Railways

Diversified our scope to Power Electronics products in Indian Railways' Rolling Stock.

MOSFET based Voltage Regulators for Motor Generator Sets of DC EMUs, in Indian Railways

Developed energy-efficient electronic lamp ballast for Railway Coaches

DC-DC Converter for Head Light Application in Indian Railways in place of Rheostat controlled headlights

The company's major thrust had been in manufacturing specialized Industrial Control products for Burner and Pollution Control- UV Flame Detector and Amplifier and a Microprocessor-based Back Feed Sequence Controller. Having more than 10000 installations in India and abroad, the above products were supplied in Steel and Cement Plants, Oil refineries and Chemical Industries

At Signotron, we endeavour to constantly upgrade to achieve future growth and maintain the highest quality of our products and services, and we do so.

We aim at the #1 position in the industrial and power electronics field in India. Our foremost priority is to comply with all statutory and regulatory requirements of our valued customers and continually improve the effectiveness of our quality management system as per the international standard ISO 9001: 2015.

We have established and regularly review our Quality Objectives based on this Quality Policy, ensuring that this policy is communicated to and understood by all within the organisation and relevant interested parties.

Signotron has established in-house modern manufacturing & test facilities to work with.

Some of the major types of equipment related to Quality are:

*** All the units mentioned above are being regularly checked and calibrated and certified as per ISO 17025 standard by NABL accredited labs.

Other critical tests like:

-are done through different government NABL accredited laboratory & institutions like ERTL, NTH, SAMEER & IIT.

ISO 9001:2015, the international standard specifying requirements for quality management systems, is the most prominent approach to quality control management systems. Key performance indicators that we follow are:

Our management aims to build an effective work culture with a positive approach towards work, high employee morale, measurable productivity and a strong focus on safety and health.

ISO, RDSO, RITES and private consignees conduct regular and frequent

inspections.

There is also an intra-company provision for compliance with

prescribed quality standards. This involves inspection at an individual component

level to assess quality compliance with the originally required criteria. All

parameter data is duly reported to the management. Deviations from prescribed

standards are either corrected or eliminated at the first occurrence.

Signotron Tower Plot J1-6, Block - EP, Sector - V, Salt Lake Electronics Complex, Kolkata - 700 091

03323573481